hyena overland

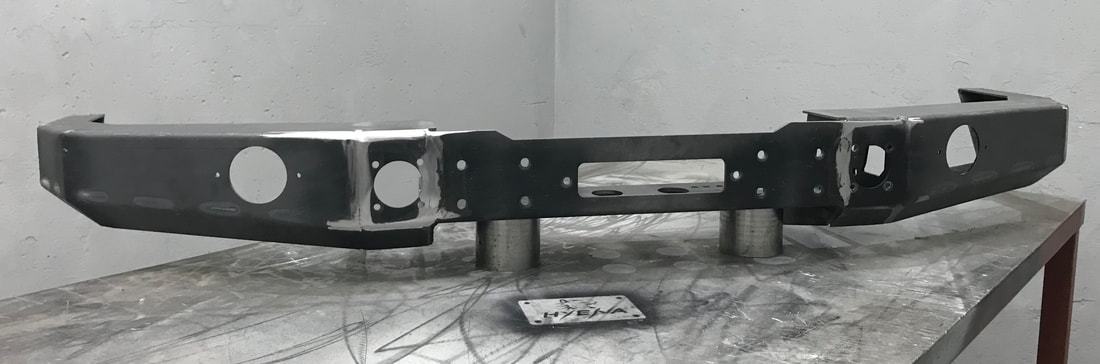

We produce professional and bespoke parts and equipment for off-road, expedition, overland and motorsport vehicles. Based on our experience, commitment and passion we aim to develop the best quality products and our mission is to keep our fresh minded designers working to improve our Hyena parts everyday for our customers.

As an added value we identify customer needs and supply to their demands.

As an added value we identify customer needs and supply to their demands.

Production

All of our products are made with high quality materials and are laser cut to define all of the details. The accessories are welded, assembled and prepared on our site in Poland where the production line is.

We are a well assembled team of hard working and passionate people. Our aim is to be the best in every part of the company.

We are a well assembled team of hard working and passionate people. Our aim is to be the best in every part of the company.

Painting Process

All Hyena’s accessories are powder coated in a high quality standard method. It is characterized by a very smooth surface, free of any scratches, thickening or embossing. It is distinguished by high protection against corrosion, chemical, atmospheric and mechanical damage. To prepare the surface, all details are shot blasted. We are powder coating in a double coat technology with a zinc layer before the finishing coat. Some of Hyena’s under body guards are hot-dip galvanized. Our partner in all painting processes is Bedo-Technology.